We regularly get specific application questions, and we will post the most common ones.

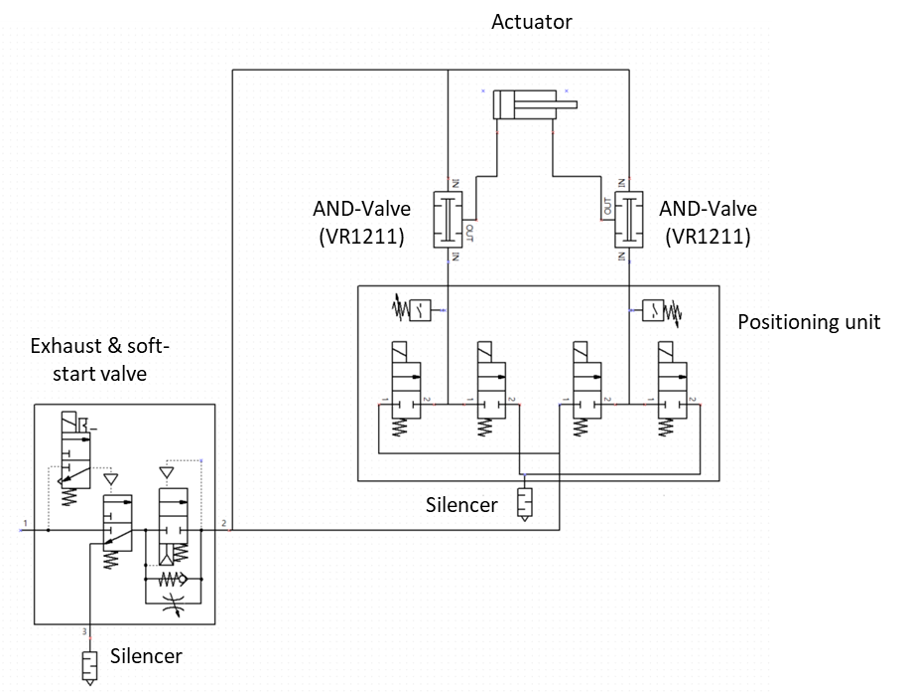

On emergency stop or during service, it is common to exhaust the air. This is extra important on pneumatic actuators as they stand for a lot of the mechanical movements. The application will determine what you want your actuator to do. In some case, you want the actuator to stay in position (which is our standard setup), and in some cases you want the actuator to loose all power so it can be moved by hand. Below is an application example, where our positioning unit is used for a positioning application with a pneumatic actuator. AND-valves are connected to the exhaust, which will release all air inside the actuator. Our positioning unit will sense that the air is gone and reduce valve cycling to 20Hz, and continue with positioning as soon as the air is returned. As the unit is using a closed loop controller, you will always know the position from the monitor signal, even if the actuator is moved by hand. video on https://www.youtube.com/watch?v=nS1YkTarxjI