We have several customers that want to control pneumatic gripper fingers.

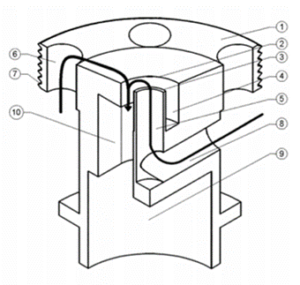

Often they want to control the finger positioning to reduce cycle time. There are also many cases where they use the grippers for other applications than gripping, for example Centering, pushing etc. To demonstrate our technology and the capabilities with our flexible positioning unit, FPU, we have uploaded a video on our Youtube channel. In this video, you can see how we position the fingers into different positions on an SMC MHL2 pneumatic gripper with D-MP position sensor. You can also see live feedback on a graph, where we present the control signal and the actual position. You can control any standard pneumatic actuator with our unit, simply add a standard analog signal (4-20mA, 1-5V, or 0-10V) for required position. There is also a feedback signal of the same type.

The video can be seen at: https://youtu.be/LcmorPuFzAo

How does this work?

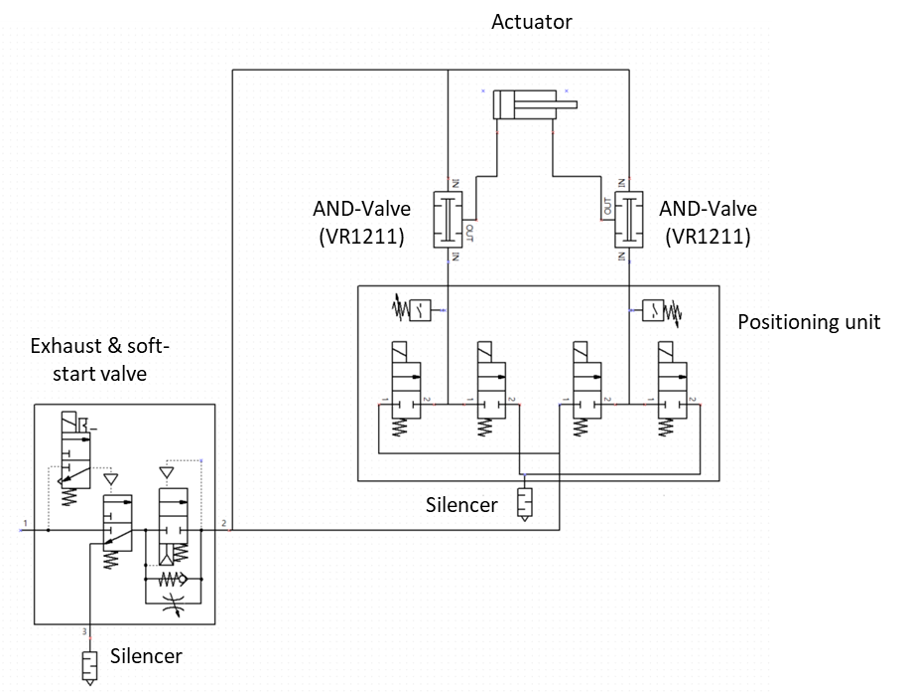

Our positioning unit use 4 extremely fast 2/2 valves, 2 for each actuator chamber, one for exhaust and one for supply. It also monitors the pressure in each chamber with pressure sensors, actual position with the help of a position sensor. The internal regulator that calculates how to control the valves uses a closed loop PID-Controller.

How is this unique?

We turn analogue Pneumatics into digital Pneumatics.

Positioning of pneumatics have, traditionally been inaccurate and slow. Our valve technology combined with advanced control achieve accuracy and speeds earlier not seen in pneumatics.

Contact us for your control needs of pneumatic actuators. We can work with standard rod based actuators, double rod type, rodless, grippers, and also rotary tables and air motors. We can also supply you with complete systems with actuators and sensors etc. We have a lot of application experiences, so feel free to ask for advise.

We look forward to connecting with you!